Making

-

Our production process

Here I'll be explaining the process we use for forming the main part of our knives, the blade. First, we convert the hard drawn blade plan into CAD data, and then use to convert the plan into NC data. We then begin the maching process in our machining center. Next, the blades are heat treated and then corrected if any distortion has occurred. We then use whetstone to begin the grinding process. Our specular surface is created by gradually decreasing the grit of the whetstone, moving through #400,#800,#1200 and finally #2000. This is a very time-consuming process because if any scratches occur, the blade must be returned to the previous step for re-finishing. Then, the blade is put through a SMAP process and the Specular surface is completed through a buffing process. The tip of the blade is finished by one of our custom proprietary machines, The Super-finisher.The above process applies to our Honzukuri and Shinogizukuri blades.

Here I'll be explaining the process we use for forming the main part of our knives, the blade. First, we convert the hard drawn blade plan into CAD data, and then use to convert the plan into NC data. We then begin the maching process in our machining center. Next, the blades are heat treated and then corrected if any distortion has occurred. We then use whetstone to begin the grinding process. Our specular surface is created by gradually decreasing the grit of the whetstone, moving through #400,#800,#1200 and finally #2000. This is a very time-consuming process because if any scratches occur, the blade must be returned to the previous step for re-finishing. Then, the blade is put through a SMAP process and the Specular surface is completed through a buffing process. The tip of the blade is finished by one of our custom proprietary machines, The Super-finisher.The above process applies to our Honzukuri and Shinogizukuri blades.

-

Blade shape

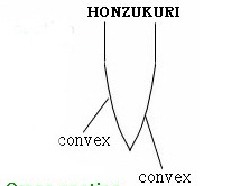

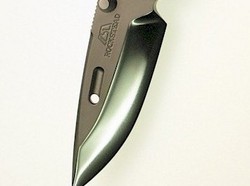

We created our "HONZUKURI" blade shape was with the Japanese sword in mind. We took the best attributes of the Japanese sword, invented a remarkably strong blade and cutting edge, and applied them to our knife. Both sides of the Honzukuri blade are convex. This cutting edge shape functions perfectly, however it is time consuming to produce and therefore expensive. As a result of our continued research, we came to the understanding that the angle along the very edge of the blade has a strong influence on its sharpness. So, we then began the work of developing our custom-grinding apparatus and as a result, the Shinogizukuri blade shape was born. As for our Shinogizukuri blade, each side of the blade is composed of 2 planes. Shinogi is the Japanese word that describes the line created by the meeting of two surfaces. With this manufactureing process, we had developed a completely new and advanced technology. We realized that the optimal blade edge angle is 30 degrees near the haft, and the optimal blade edge angle is 24 degrees near the top of the blade. We made the adjustment to a blade angle of 30 degrees near the haft in order to achieve improved toughness, because this is where the highest stresses occur.We then made the adjustment to a blade angle 24 degrees near the tip of the blade with the aim of superior sharpness in mind, because high stresses do not easily occur here. From haft to tip is pne continuous, gradually reducing angle. The result of our advanced manufacturing process, is a blade that's well suited to human use, and is highly recognized for its sharpness.

We created our "HONZUKURI" blade shape was with the Japanese sword in mind. We took the best attributes of the Japanese sword, invented a remarkably strong blade and cutting edge, and applied them to our knife. Both sides of the Honzukuri blade are convex. This cutting edge shape functions perfectly, however it is time consuming to produce and therefore expensive. As a result of our continued research, we came to the understanding that the angle along the very edge of the blade has a strong influence on its sharpness. So, we then began the work of developing our custom-grinding apparatus and as a result, the Shinogizukuri blade shape was born. As for our Shinogizukuri blade, each side of the blade is composed of 2 planes. Shinogi is the Japanese word that describes the line created by the meeting of two surfaces. With this manufactureing process, we had developed a completely new and advanced technology. We realized that the optimal blade edge angle is 30 degrees near the haft, and the optimal blade edge angle is 24 degrees near the top of the blade. We made the adjustment to a blade angle of 30 degrees near the haft in order to achieve improved toughness, because this is where the highest stresses occur.We then made the adjustment to a blade angle 24 degrees near the tip of the blade with the aim of superior sharpness in mind, because high stresses do not easily occur here. From haft to tip is pne continuous, gradually reducing angle. The result of our advanced manufacturing process, is a blade that's well suited to human use, and is highly recognized for its sharpness.

-

Mirror surface processing

When looking at a regular knife-edge through a microscope, it appears serrated like the blade of a saw. We came to the realization that the nicks that can occur in a blades edge, are largely as a result of these microscopic, random protrusions and imperfections that are present in most blades, and that in order to avoid the problem of nicks, the blade has to have a perfect mirror surface. You can confirm the difference in the feeling between a regular knife edge and our knife edge, when you touch a Rockstead knife-edge. Slicing through a sheet of paper will confirm Rockstead's unrivaled sharpness.

-

Function

We demonstrate our Rockstead knife at knife show all over the world. After cutting completely through a 25mm manira rope 1000 times, our ZDP189 blade is still more than capable of cleanly slicing through a sheet of paper. This is only possible as a result of ZDP189's excellent hardness of HRc67. Blades made from YXR7 can cut or chop through dried bamboo and still be able to slice through a sheet of paper. YXR7 blades can also cut through a 25mm manila rope apporoximately 500 times while still maintaining their sharpness. Our BEETLE DLC model was featured in the American knife magazine "Tactical Knife" where it was subjected to 3 months of cardboard cutting by a blade-testing machine. Upon the conclusion of the testing, the Tactical Knife article reported that the sharpness was wonderful.

We demonstrate our Rockstead knife at knife show all over the world. After cutting completely through a 25mm manira rope 1000 times, our ZDP189 blade is still more than capable of cleanly slicing through a sheet of paper. This is only possible as a result of ZDP189's excellent hardness of HRc67. Blades made from YXR7 can cut or chop through dried bamboo and still be able to slice through a sheet of paper. YXR7 blades can also cut through a 25mm manila rope apporoximately 500 times while still maintaining their sharpness. Our BEETLE DLC model was featured in the American knife magazine "Tactical Knife" where it was subjected to 3 months of cardboard cutting by a blade-testing machine. Upon the conclusion of the testing, the Tactical Knife article reported that the sharpness was wonderful.

-

Processing of blade nicks

Please allow us here at ROCKSTEAD to repair any blade nicks if you are not able to repair them yourself. In this case, you are responsible for paying the shipping fee and the blade nick repair fee. We will contact you with blade nick repair fee estimate upon receipt of your knife. If you decided not undergo the blade repair, we will only re-grind the blade and return it to you. However, in principle the repairing of our knife is free.

-

DLC coating (Diamond like carbon coating)

The coating process is achieved by bonding the carbon to the knife in vacuum oven. The oven is heated to 500 degrees Celsius, achieving a surface hardness near to that of a diamond approximately Hv1800. The thickness of the coating is 3 microns. This coating is used to outstanding effect when applied to YXR7 steel. This is because of the steels high hardness of HRc65 and intrinsic durability. If an impact is received on the surface of the DLC coating, the shock is dissipated by the YXR7 steel and prevents any cracks from occurring. This is not the case if the DLC coating is applied over a softer steel. Even though the DLC is of an extreme hardness, when applied over a softer steel, a coating of 3 microns will be destroyed at once.

The coating process is achieved by bonding the carbon to the knife in vacuum oven. The oven is heated to 500 degrees Celsius, achieving a surface hardness near to that of a diamond approximately Hv1800. The thickness of the coating is 3 microns. This coating is used to outstanding effect when applied to YXR7 steel. This is because of the steels high hardness of HRc65 and intrinsic durability. If an impact is received on the surface of the DLC coating, the shock is dissipated by the YXR7 steel and prevents any cracks from occurring. This is not the case if the DLC coating is applied over a softer steel. Even though the DLC is of an extreme hardness, when applied over a softer steel, a coating of 3 microns will be destroyed at once.

-

DLC-Prism coating

The coating process is the same DLC coating. However, some of details are different things. The oven is heated to 400 degrees celsius, achieving a surface hardness near to that of a diamont approximately Hv3000. And the thickness of the coating is 0.3 microns.

At this time, we use this special coating to the titanium handle. Because, this coating color is very nice gradation.

Please note : This coating color will be a subtle difference for each handles.

The coating process is the same DLC coating. However, some of details are different things. The oven is heated to 400 degrees celsius, achieving a surface hardness near to that of a diamont approximately Hv3000. And the thickness of the coating is 0.3 microns.

At this time, we use this special coating to the titanium handle. Because, this coating color is very nice gradation.

Please note : This coating color will be a subtle difference for each handles.